Climate Transition Plans: Decarbonisation is only one part of the puzzle

by James Balik-Meacher

View post

There is a lot of focus in the general media and from government on the Food & Drink sector, especially with food waste and plastics. But there is also a recognition of the importance of the sector to the UK economy with the first meeting this year of the Food and Drink Sector Council and the continued funding for support to food waste reduction.

This has driven actions on changes. For example, on plastic packaging, and discussions on sell-by/use-by dates. There is continued drive through the supply chain to have strong environmental credentials, reporting carbon footprints, reporting energy use and waste: and reducing them. There are elements of compliance with changes to IS14001 in the 2015 version to be more active around improvement through life cycle thinking and risks and opportunities.

Whilst addressing these challenges is a good thing, in times of pressure on sales and margins it can be seen as a cost to the business to achieve. But sometimes the business decision process can omit or under estimate the benefits, especially the potential for business performance improvement. In many cases this can mean the ‘good’ can be achieved with a net business financial gain.

Last year the House of Commons Environment, Food and Rural Affairs Committee response+ to the Food Waste in England report identified 10 million tonnes of wasted food and drink, of which 70% is household and 30% from other sources – businesses? + HC 444, 17 October 2017

The financial measure of waste in most businesses is the cost of a waste management contract. Wasted water almost literally goes down the drain, and, alongside wasted energy, often built into the site utilities budget.

There has been a lot written over the years about the ‘True Cost of Waste’. In essence this is realising that the real cost of your solid and liquid waste is built up of the price of the raw materials and the value of the work done on those materials (in terms of labour, utilities and equipment). WRAP published work[1] showing food waste costing £90 per tonne to dispose of actuals costs the business £3,000 per tonne, so is well worth reducing.

There is also strong understanding that bringing a focus onto your waste (be that solid or liquid, gas or electricity) improves the overall process. Root-cause analysis of how solid waste occurs can lead to raw material and energy savings and maintenance and quality improvements.

[1] The True Cost of Food Waste within Hospitality and Food Service, WRAP 2013

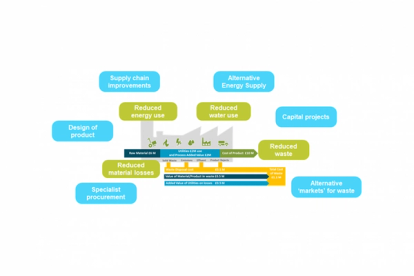

Start in the middle, understand the where and what of your waste. Then investigate to find the root cause. Then put in place actions to reduce the use of utilities, use of materials and of rejects (often no and low cost). Then move out from that base and look at better waste disposal, more appropriate waste contracts, bigger projects. Don’t start on the outside with large capital projects based on current usage and waste as you may end up locked into an outsized solution.

So, when you are looking into meeting the demands of markets, supply chains and internal performance improvements consider the potential inherent in what you dispose of, and don’t throw away the chance to improve.

[1] The True Cost of Food Waste within Hospitality and Food Service, WRAP 2013

In 2011 a Defra report++ on the Food and Drink sector suggested £219million in waste related savings and £75million for water.

Is the potential still there in your businesses? + SPMT09-070 (ev0441): Further Benefits of Business Resource Efficiency, 2011

by James Balik-Meacher

by Peter Lo

by Melissa Birch, Tarra Tamang