Getting acoustic ceilings right: Common pitfalls and how to avoid them

- Post Date

- 24 June 2025

- Read Time

- 6 minutes

With the rise of mixed-use buildings, it’s becoming more common for noisy mechanical rooms, gyms, and other high activity spaces to be situated above or below quiet areas like bedrooms, classrooms, or clinics. Sound transfer becomes a significant concern, highlighting the importance of well-designed sound-isolating ceilings and their integration with the overall building design.

While base building designs address structural needs, developers, architects and designers also need to consider acoustic comfort for residents, users and visitors.

What is a Sound Isolating Ceiling (and Why Should You Care)?

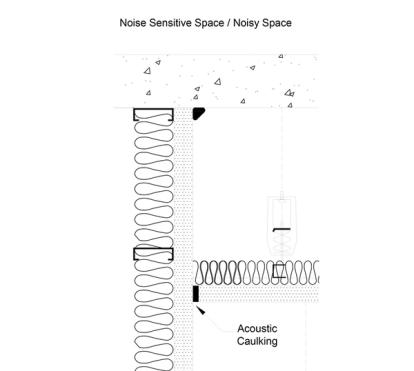

Generally, a sound isolating ceiling sits below the structural slab and comprises four essential components: drywall, acoustic insulation, sealant, and resilient hangers. It looks something like in the sketch below.

There are some important specification details to consider when designing an acoustic ceiling. These details are important to maintain the acoustic performance of the separation between spaces, especially for multi-use buildings.

Common Pitfalls that Undermine Acoustic Performance

Penetrations

- Introducing holes and gaps in the sound isolating ceiling, (e.g., pipes or conduit penetrations)

- Components penetrating through that touch the structure

- Holes and gaps with non-existent or poor acoustic seals

Location of Building Services

- Generally, pipework penetrating the structural slab should be located above the sound isolating acoustic ceiling, with pipes and ductwork serving the space below located below the sound isolating acoustic ceiling.

- HVAC ductwork or plumbing passing through a ceiling/floor can cause issues with sound transfer and noise from its use. Care should be taken to place these in a location that doesn’t reduce the performance of the sound isolating ceiling. We often see acoustic performance undermined when multiple trades install services without coordinated routing. It isn’t one solution fits all - location selection based on your situation is critical.

- A finished ceiling will have openings for light fixtures, sprinklers, ventilation, speakers, etc. These penetrations are part of the building design but should be in a secondary ceiling below the sound isolated ceiling.

Construction Challenges We See Again and Again

Design drawings often accommodate sound isolating ceilings as recommended by the acoustics consultant. This is typically relayed early in the design so that the slab-to-slab height can be adjusted adequately, and spandrel panels on the facade are included to block the ceiling from view. However, these design measures are not always sufficient to accommodate everything that goes on in the ceiling cavity, and challenges can arise during construction. Some of these challenges include:

Trade Coordination Issues

Often the trade installing services such as plumbing and HVAC are not aware of acoustic ceiling requirements, or they simply do not know the importance of keeping services separate. This can cause challenges for the drywall trade installing the acoustic ceiling.

Not Enough Ceiling Height

Sometimes the cavity between the finished ceiling and the underside of the structure above remains limited such that there is not enough space to accommodate all the services while also isolating noisy space services within the sound isolating ceiling.

Termination of the Acoustic Ceiling

Sometimes, only a partial sound isolating ceiling may be possible or practicable. In such cases, the ceiling should terminate at a bulkhead or structural beam to maintain the same level of acoustic separation at the perimeter. This is sometimes missed during construction.

On-the-Spot Modifications

Some materials specified in the design may not be available for purchase or need to be replaced by a more economical alternative during the construction phase. Not knowing how the change affects the acoustic performance and selecting the wrong alternate product can reduce the performance of the acoustic ceiling, resulting in noise issues after construction.

Avoiding the Most Common Acoustics Design Coordination Pitfalls

Several strategies can be implemented to minimize complications during construction:

Encourage coordination between trades: This helps support the smooth installation of services and the acoustic ceiling. Ensure trades know the elevation their services should run.

Use site instructions: These documents can be prepared to ensure trades know there will be an acoustic ceiling installed. These should also indicate the location of each service in relation to the others.

Regularly inspect trade's work: This is to identify construction deficiencies and errors early and resolve them with minimum impact.

Plan for enough ceiling space: Ensure this is provided during the design phase for trades to be able to separate services adequately.

Avoid unnecessary gaps and holes: Ensure penetrations through the sound isolating ceiling are kept to a minimum, and if needed, these are properly sleeved and sealed.

Avoid window-to-ceiling interference: During design, windows should be sized so that they do not interfere with the required ceiling space. This is particularly important in spaces directly below mechanical rooms or other noisy spaces.

Inform the project acoustic consultant of changes: Keep the project acoustic consultant informed of the construction progress, and of any modifications that need to be made to ensure the acoustic environment within noise sensitive spaces is not compromised.

Key Takeaways

- Sound isolating ceilings only work if coordinated early and built correctly

- Poor trade coordination and penetrations are common pitfalls

- Leave enough ceiling space, and plan for penetrations

- Always involve your acoustic consultant in changes

- Fixing mistakes after construction is expensive, prevention is always better

Making Acoustic Ceilings Work

Preventative measures can help reduce construction challenges that can hinder the acoustic separation between noisy and noise sensitive spaces.

Despite having these measures in place, there are still many challenges that can arise during construction. For this reason, it is important to include the project acoustic consultant in modifications and decisions where changes could result in reduction of acoustic performance and possible noise disturbances.

Remediation work can be very costly after construction is fully completed, so alleviating potential issues during design, and addressing issues promptly during construction, is beneficial from both a schedule and cost perspective.

Acoustic consultants can highlight where changes could increase the risk of complaint, provide site instructions, recommendations for alternative solutions, and ultimately remediation solutions before spaces are fully finished.

Want to avoid future headaches and get it right the first time? Loop us in early and we’ll help you get it right from the start.

Recent posts

-

-

Unlocking value through solar PV repowering: A focus on module replacement and DC/AC optimisation

by David Fernandez

View post -