Port of Astoria Byproduct Recovery Center Feasibility Study

- Client Name

- Port of Astoria, Oregon

- Location

- Astoria, Oregon, United States

Challenge

The Port of Astoria faced mounting regulatory pressures and operational challenges related to seafood-processing wastewater, driven by stricter effluent discharge limits set by the Oregon Department of Environmental Quality (DEQ). To address these challenges and support industry growth, the Port explored a forward-thinking solution: a centralized Byproduct Recover Center (BRC).

Rather than requiring each individual processor to develop its own costly independent treatment system to meet the Oregon Department of Environmental Quality’s stringent NPDES permit requirements, establishing a centralized BRC would consolidate wastewater treatment into a shared facility managed by the Port.

This approach reduces costs, improves compliance, and fosters sustainable economic development, while ensuring wastewater meets strict state effluent standards to maintain high water quality in and around the mouth of the Columbia River.

Solution

SLR was selected to lead a comprehensive FEL1 feasibility study because of its deep technical expertise in wastewater engineering and regulatory strategy. SLR conducted the following modeling, testing, and analyses while additionally engaging with the state to explore permitting pathways:

- Bench-scale treatability testing to validate treatment performance.

- Monte Carlo flow/load modeling for robust system design.

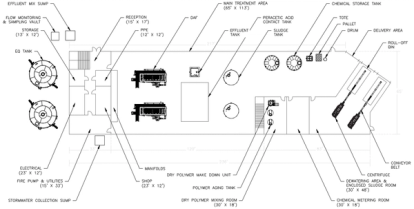

- Conceptual design of two advanced treatment technologies:

- Dissolved Air Flotation (DAF)

- Advanced Foam Separation (AFS) by Aqua-Terra Consultants

- Mixing zone analysis using CORMIX for treated effluent discharge

- Infrastructure planning and phase cost estimates to support implementation.

The resulting findings presented by SLR positioned the Port to advance toward permitting and construction with confidence.

Impact

SLR’s feasibility study demonstrated that a centralized Byproduct Recovery Center could reduce seafood processor costs, improve pollutant removal efficiency, and eliminate the need for individual NPDES permits.

The proposed facility would treat up to 2.2 MGD, recover organic byproducts, and support sustainable economic development. With an estimated capital cost of $15.7 million and an annual operating cost of $1.35 million, the project sets a precedent for similar coastal communities seeking sustainable, cost-effective solutions.