Reimagining pharma packaging: A case study in collaborative decarbonisation

- Post Date

- 29 July 2025

- Read Time

- 9 minutes

Can one partnership decarbonise an entire industry? Is system-wide transformation possible? The pharma sector tried. We examine if they succeeded and what others can learn.

The pharmaceutical industry is notoriously wasteful. Strict standards for sterility and safety lead to the use of ultra-secure packaging and device production practices. They can significantly drive up costs for both patients and healthcare providers and have a considerable environmental impact.

To solve this conundrum, a group of companies in the pharma supply chain came together to form the Alliance to Zero [1]. While they worked on many different topics, one of them was on a solution to one critical packaging item, and exemplifies how a small group can make a huge difference [2]. Along the way, they also learned lessons about how to make multi-stakeholder partnerships work even more effectively. Even better, the genesis of the idea started one evening over a good dinner.

Case study: Decarbonising the secure, blister-free syringe

In 2021, eight companies teamed up to solve the challenges of decarbonising their own companies, products, and supply chains. They realised that to have a significant ecosystem impact, they would need to do more than just engage with their own suppliers. They had set ambitious climate goals individually and were now looking at the hard reality of how they could achieve them, and how they could affect broader changes across their industry.

Rallying under the Alliance to Zero, these eight companies represent the supply chain for an injection device (similar to autoinjectors used in diabetes treatment):

- SCHOTT Pharma, which manufactures glass and polymer containers such as syringes to safely store the various drugs

- Datwyler, which manufactures the rubber stoppers and any other rubber components needed for drug packaging

- Ypsomed, which manufactures injection device systems like insulin pens

- Schreiner MediPharm, which manufactures functional labels

- Harro Höfliger, which designs and manufactures the machines that assemble the devices

- Körber Pharma, which manufactures final packaging as well as designing state-of-the-art machines for automated inspection and final packaging

- Sharp, which assembles the product and places it in its final packaging

- Resourcify, which is a digital solution provider to guide waste streams into the circular economy

Ready-to-administer syringes, or prefilled syringes, offer significant advantages for hospitals by eliminating the need for manual measurement of medication and reducing the exposure of needles and drugs to non-sterile environments. They are also tamper-resistant and protect against theft and improper use. However, they are traditionally packaged in a “blister”, or plastic pre-moulded package which is entirely non-recyclable and creates a huge amount of waste daily.

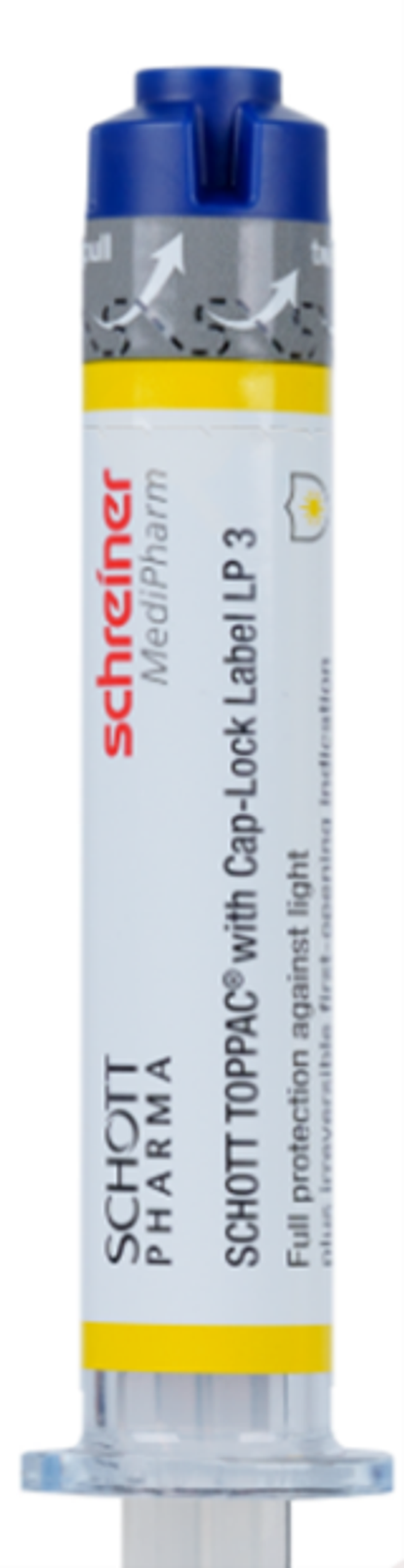

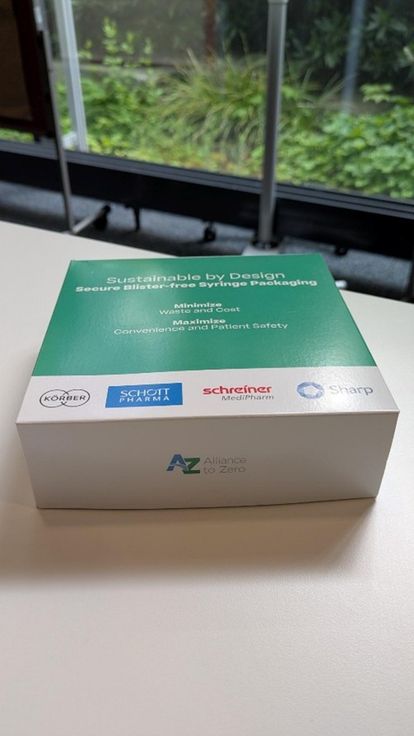

So SCHOTT Pharma, Schreiner MediPharm, Körber, and Sharp joined forces in a working group of the Alliance to see if they could come up with a better solution that would solve all of the same issues the hospitals were facing, while still reducing waste as much as possible. The result was a new product – the Secure Blister-Free Syringe (SBSF). This product eliminated the need for the blister, without compromising on sterility or security features. SCHOTT designed a new syringe with a cap of the same diameter as the body of the syringe, Schreiner MediPharm designed a label that covered the cap and provided proof of opening, Körber came up with a box manufactured from single-material sustainable cardboard and optimised for these new devices, and Sharp provided the final assembly.

Huge carbon and waste savings were realised

The implications for benefits along the value chain and for carbon and waste savings are eye-popping. Even though these are small devices in one part of the pharma industry, their ubiquity and sheer volume means that by adopting this new device, an entire industry could be moved. That is exciting. Some of the benefits are as follows:

- Reduced cost and complexity: Because no blister packaging is needed, the associated raw materials, manufacturing, machine and inspection needs are entirely absent from the process, thus reducing cost and in turn the length and complexity of the supply chain.

- Lowering logistics and emissions impact: Due to the higher packing density this new system allows for, there are significantly lower logistics and carbon costs for transport (e.g. for 10 million shipped syringes, the new blister-free packaging requires 67 shipping containers, compared to 83 containers for standard blister packaging, saving 16 containers and approximately $104,000 in shipping costs and reducing the carbon footprint by 1,698 g CO2/kilometre).

- Less waste: Transitioning to the Secure Blister-Free Syringe also results in 80% less plastic and packaging waste compared to traditional blister packaging. For 10 million syringes, this equates to saving 34 tonnes of plastic.

- No regrets: The issues that the blister was originally designed to address have been met in an elegant and more efficient way without sacrificing safety, integrity, or ease of use for hospital staff.

When the original idea behind the Alliance was to come together as a formal group and begin with harmonising language between the companies and agreeing on specific goals. It became clear early on that there were several places where they could help each other:

- Sharing knowledge, and best practices, and resolving to come together in person bi-annually and learn from each other.

- Completing an in-depth product carbon footprint for one of their shared products in order to clearly identify the hotspots.

- Solving challenges that they could see between the companies could only be accomplished with full collaboration and trust.

There would be no decarbonisation without circularity

Their first large collaborative task was a complete product carbon footprint for one of the devices that they produced as part of a pharma supply chain. By going in depth within each company and using primary data, they were able to clearly see where the hotspots were. They were surprised by the results, which showed that over 50% of the footprint came from raw materials and end-of-life processes. Therefore, they quickly realised that there would be no way to decarbonise their products without circularity. One insight led to another, and the deeper they looked, the more interconnected the challenges became. They enlisted help. They sponsored graduate projects with universities and brought in consultants and experts as needed. They formed working groups within the Alliance that would each focus on solving different aspects of their ultimate mission – to facilitate the transition of the pharma sector to net zero in line with the goals of the Paris Climate Agreement for the devices which they could directly affect (injection devices such as an insulin pen).

As time progressed, they were able to begin publishing papers, presenting at conferences, and rapidly becoming a trusted voice in the industry. They were also able to check back against their original decarbonisation goals for each company and for their products and see the tangible results. But perhaps the most unique and intriguing output was what they could create between companies that could not be created alone.

Lessons learned: Is the Alliance to Zero a transferable model for multi-stakeholder partnership decarbonisation?

Multi-stakeholder partnerships (MSPs) have been around for a long time in a variety of forms. One of the most standard forms would be a trade association, where members of a given discipline come together to network and learn. These large partnerships have some very clear advantages. However, they are often so large that they can be hard to manage, tied down by bureaucracy, moving slowly and incrementally towards their goals, albeit in the right direction.

Smaller and more focused groups may not feel that they can have as much reach and influence, but the Alliance is showing that this doesn’t need to be the case. I have worked with them over the past four years as a founding member and now as part of the Secretariat. Its size, focus, and the trust that is built between members gives it efficiencies that aren’t found in larger multi-stakeholder partnerships and allows it to be both agile and creative as well as incredibly effective.

As far as I have seen, there are no disadvantages to this type of model, and the value added to the participating companies is substantial. One important consideration, however, is its suitability: it tends to work best in industries or for products with relatively short and straightforward supply chains. For example, a shoe manufacturer could be an ideal candidate, whereas a car manufacturer would face greater challenges, as it is managing several hundreds, if not thousands, of suppliers.

The huge advantage of a model like Alliance to Zero is that it allows for close collaboration between companies. They are not trying to “boil the ocean” but are trying to have a direct effect on what they can control, what they have expertise in, and what is within their sphere of influence. This allows them to create new products that are already aligned and accepted between companies while solving for sustainability simultaneously.

Another benefit that they have is the ability to pool resources for better outcomes. As a membership organisation, they all contribute annual dues, which in turn can be leveraged to spend on experts, consultants, and university partnerships. They then come together in person twice a year for a two-day meeting, where they can exchange knowledge, update each other on the projects that they are collaborating on, and continue to build on their relationships. Eventually, they can influence the broader industry and help shape the narrative by publishing papers, presenting, and offering workshops to others at various conferences.

One partnership. One product. Big impact.

Now imagine what’s possible if every sector took the same approach.

Sometimes as advisers, we can feel that the issues we face are so large and complex that they will be incredibly challenging to solve, but the Alliance to Zero shows that focusing on one segment of one industry can have an outsized impact, and that is something to be excited about.

Advisory Digest

Enjoyed this article? For more like it, get SLR's quarterly sustainable business briefing straight to your inbox.

Sign Up

-------------------------------------

References:

[1] https://alliancetozero.com/resources/

[2] https://alliancetozero.com/recources/spotlight-on-secure-blister-free-syringe-packaging/

Recent posts

-

-

Unlocking value through solar PV repowering: A focus on module replacement and DC/AC optimisation

by David Fernandez

View post -