Recycled material traceability audit

- Client Name

- Confidential

- Location

- International (China, Japan, Korea, and Switzerland)

Challenge

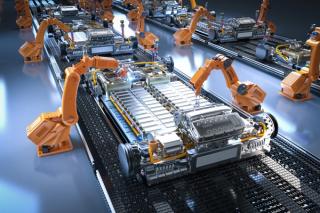

A leading electronics manufacturer, recognized globally for its innovation and scale, faced increasing pressure to substantiate its public claims regarding the use of recycled materials in its products. The company operates a vast and complex multi-tiered supply chain, with suppliers distributed across continents and involving numerous intermediaries. This complexity made it particularly challenging to trace the origin of raw materials and verify their recycled content.

In response to growing regulatory scrutiny, particularly under the EU’s Corporate Sustainability Due Diligence Directive (CSDDD), the EU Battery Regulation, and the U.S. Securities and Exchange Commission (SEC) guidelines on ESG disclosures, the company sought to:

- Prove that its suppliers have established robust material traceability systems

- Verify that the materials entering its supply chain were indeed recycled

- Identify the point of origin of these materials to ensure alignment with sustainability claims and regulatory expectations

Solution

SLR was selected for its deep expertise in responsible sourcing and global audit capabilities. The team conducted a tailored traceability audit across selected supplier sites, focusing on high-risk materials. The audit methodology was customized to meet the client’s requirements.

The audit includes document review and a site visit. During the audit, the suppliers need to provide evidence to prove that:

- The system of controls and transparency over the recycled material supply chain, including the chain of custody/traceability, had been established

- The material contained in the sampled batches entering the client’s supply chain was indeed recycled material, and the point of origin of the recycled material was properly identified

- The supplier’s internal material control system could avoid the mixture of mined materials and recycled materials

Impact

As a Tier 1 manufacturer in the electronics sector, the client now possesses a second-party verification report to support its recycled material claims. This verification significantly enhances the credibility of its public disclosures and strengthens its position as a leader in sustainable manufacturing.

The audit program not only increased the accountability of the company’s sustainability claims but also helped mitigate the risk of potential reputational damage, regulatory penalties, or litigation. By proactively pursuing higher supply chain transparency, the company has reinforced its commitment to ethical sourcing and long-term brand integrity.