Part two: Hydrometallurgy, chemical analysis and magnetic separation at SLR’s mineral processing laboratory

by Ben Simpson

View post

It is generally common knowledge that data centers consume a significant amount of energy. Whenever there is a practice or technology that can help reduce that demand, it’s worth investigating, as small energy savings can add up to large emissions reductions and yield significant cost savings.

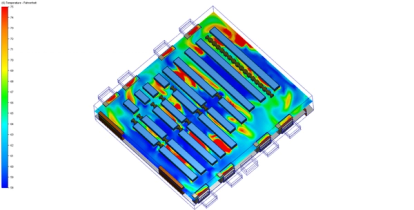

Computational fluid dynamics (CFD) modeling may sound like a mouthful, but it’s a term that refers to a relatively simple concept: testing how energy is used in a data center before it’s built or during operations so that designers can identify problem areas and fix them to achieve energy and cost savings.

CFD modeling helps data center operators and designers see how well—or not—equipment is performing (or will perform). Operators can use this insight to predict and optimize cooling needs, adjust performance to optimize outcomes (to use no more energy to cool than is necessary), and thus save on energy costs.

All CFD projects begin with the development of a true-to-reality, three-dimensional, computer-generated (CAD) model of a system, in this case, the airflow within a data center. From there, thousands of key inputs, such as equipment wattage, air temperatures, airflow volumes, floor tile openings, etc., are entered into the model as influencing data. The model is then analyzed to examine the airflow dynamics within the building, e.g., how air circulates through the data center infrastructure, making the invisible (air) visible.

Many data centers are cooled by either blowing cold air directly onto the servers and equipment or by pushing air into the room through perforated tiles under a raised floor. These designs, while practical, create many potential problems:

In both of these cases, poor airflow can cause hot air to build up, leading to server damage, performance degradation, hardware damage, and/or partial/complete system failure.

Without CFD modeling, a data center operator may only assume that their design is without flaws. CFD helps reveal true areas of concern through visualization and modeling that can show slow progressive damage over time, along with acute design failures.

SLR has CFD experts with real-world data center experience who can run CFD analyses early in the design phase of construction, identifying areas in the design that may indicate future problems. We can help you identify and assess critical design issues such as areas with uneven cooling, hot spots, and recirculation zones.

For existing data center operations, SLR can provide CFD modeling to analyze the efficiency of an existing cooling system, identify ongoing issues, and provide data for informed decision-making and revisionary system adjustments.

Beyond improving cooling efficiencies through direct air observation, CFD modeling can also be applied to understand how equipment location impacts efficiency. Optimizing server rack layouts and equipment placement can be modeled in different configurations to allow a data center operator to ‘plan the move’ for maximum performance and energy savings.

SLR is a global environmental and advisory consulting firm, providing strategic, engineering, and data-focused solutions to our customers. Our experts across multiple technical disciplines provide industry-leading support to data centers—from concept to feasibility and planning to delivery. Our solutions are supported by robust data and science-based modeling, which add direct value and minimize operational risks.

Want to find out more? Our Global Data Center Solutions playbook showcases SLR’s capabilities and experience working in this area.

Click to download

by Ben Simpson